Cape Town boxing club owner Arran Mckenzie, owner of Mckenzie Quail Farm in Atlantis, always dreamt of being self-sufficient, so he planted vegetables and bought 12 quails as part of a farming experiment to see if he could grow and raise healthy, ethically produced food for his family.

“I chose quails because their meat and eggs are three to four times more nutritious than chicken meat and eggs,” Mckenzie explains.

The birds were kept in a home-made tractor, which he moved every two days to maximise their foraging. “Most of the birds came from a cage-reared background, so it was amazing to give them an opportunity to roam outside,” he says.

Despite some initial problems with cats and rats, the birds thrived, so in 2016 Mckenzie decided to take his experiment to the next level by renting 10ha of land near Atlantis. There was already old pig housing on the farm, which he used to begin raising quails commercially.

Having access to land also allowed him to expand his vegetable production, primarily from heirloom seed, to supply a restaurant that was looking for an organic supplier. In addition, he started keeping Boschveld chickens, Dorper sheep, as well as dwarf and Boer goats.

“The dwarf goats produce exceptionally creamy milk with a high [percentage of] butterfat, but they are difficult to milk because of their small teats,” he says.

The market

In only a few years, Mckenzie managed to increase his quail production to roughly 3 000 birds which, in hindsight, he feels might have been too many, too fast. He supplies the meat and eggs to various butcheries, some Spar stores and restaurants, and other buyers.

“I slaughter and process the birds on the farm, as I feel it is more humane than subjecting them to a trip to an abattoir, where I have no control over what happens to them,” he says.

The market for quail is nevertheless limited, with demand declining drastically over the past year due to the impact that COVID- 19 and the lockdown measures had on the economy.

Mckenzie explains that quail is still considered a niche product, and therefore one of the first things to fall off shopping lists when consumer spending is under pressure.

It also doesn’t help that quail costs more than twice as much as chicken.

“It’s more expensive to produce quails than chickens, as the birds require a higher-protein feed of roughly 28% in comparison with a broiler starter ration that averages between 18% and 20%. [Quails] are also much more labour-intensive to pluck, clean and process,” he says.

Another issue is that people generally assume quails are wild birds, whereas most are produced in battery cages. In effect, people don’t check whether the birds are ethically produced.

“It’s much cheaper and easier to raise quails in cages than to give them as much space as we do. But I can’t raise them in cages; it’s cruel and unnatural.”

With the decline in demand, Mckenzie scaled his flock down to 200 birds, and is still contemplating what he should do with them. Egg production usually starts to wane once the birds have reached nine months old, so breeders then have to be replaced.

“When I started out with commercial production, my hatching percentage was a dismal 30%. Many of the hatchlings were deformed and mortality rates were high. To address this, I put a lot of effort into improving the genetics of my flock, sourcing genetics from all over South Africa and even overseas. I guess I could sell genetic material to other producers, but my heart has always been set on the production of healthy, ethically produced meat, from field to fork.”

Farming methods

Mckenzie stocks a mix of Japanese and Golden Giant quail, and has managed to significantly increase the average processed weight of his birds thanks to selective breeding. The broiler birds are slaughtered at six to eight weeks, depending on their weight; restaurants prefer birds with a processed weight of around 220g.

According to Mckenzie, quail production is ideal if you’re looking for an easy way to become more self-sufficient: “Quails are quite hardy birds and less susceptible to disease than chickens are, but should preferably be kept away from chickens for biosecurity reasons. We separate the chickens and quails and change our clothes before moving from the one to the other.”

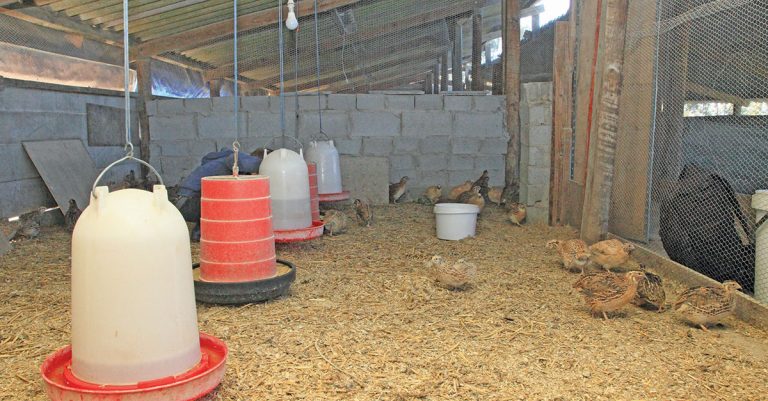

Since he practises organic farming, Mckenzie uses only natural remedies to treat and keep the birds healthy. The production environment is also kept as close to nature as possible, with low stocking densities, to prevent stress and promote animal welfare.

Mckenzie says he has never suffered any serious losses to disease, except for one year. He was advised to vaccinate the birds to prevent additional losses, but instead culled the sick ones and medicated the rest with a his own concoction of apple cider vinegar and liquidised garlic and aloe vera.

“To ensure uptake, the birds were thirsted for a day before receiving the treatment for a week via their water. I’m not saying it’s a cure, but it worked for my quails and chickens,” he says.

Garlic is used to keep internal parasites in check, while boxes filled with diatomaceous earth are placed inside each production unit for the birds to take dust baths in, which helps control external parasites.

Keeping the production environment clean is key to bird health and production success, he says. However, it is more expensive and difficult than cleaning cages, where droppings can just fall to the floor and the eggs are collected via gravitation.

Unlike chickens, quails don’t lay their eggs in certain spots, making them difficult to collect. Since Mckenzie’s birds are kept on the ground, their eggs must be collected three times a day, or the birds will start to peck at and damage them which, in turn, will cause the bedding to get wet.

He uses pine shavings as bedding, which has to be turned on a regular basis to keep it dry and prevent a build-up of ammonia.

“The shavings are actually sifted to eliminate any sawdust, which can cause respiratory problems [in the birds].”

It is essential for the production units to be thoroughly cleaned and sanitised at the end of each production cycle before new birds can be introduced to them.

Mckenzie uses the litter in his compost, which is then used in his organic garden.

“I follow no-dig regenerative farming practices. “Our soil is really sandy and sticky, so I plant directly into ridges of a compost-topsoil mixture, which is sustained through the continuous addition of mulch,” he says.

Excess vegetables are given to the quails. Therefore, in addition to their pre-formulated high-protein rations, they also receive spinach, which is one of their favourites, broccoli, hemp and barley sprouts.

“They need their greens,” advises Mckenzie.

Rations and water are supplied via chicken bell feeders and drinkers, but Mckenzie points out that you need to lower them to ensure they are at the right height for the quails.

He also sometimes puts a bale of hay in the production area, giving the birds an opportunity to scratch and pull out hay, and cement slabs are placed against the walls to supply the birds with places to shelter.

Production Challenges

Quails are quite skittish, and often fly into things when they’re scared or anxious, so the roofs of the production units should be high enough to avoid them injuring themselves.

A drawback of quails is that they have been domesticated for so long that many of their natural instincts have been bred out of them. This makes free-range production difficult.

“Chickens look for shelter and huddle together when it rains or they’re cold. Quails, on the other hand, will just drop down where they are and freeze to death,” Mckenzie explains.

He pulls sail curtains over the windows of the units to protect the birds against the wind and cold. On sunny days, however, the curtains are kept open, allowing the birds to bask in the natural light.

“Quails love nothing more than sitting in the sun and taking dust baths. You’ll see them all sitting in a line, with their wings spread out, soaking up the sunshine.”

Since quails seem to have lost their ability to hatch their eggs, producers need to incubate the eggs within a week of collection to produce replacement stock. It takes about 15 to 18 days for the eggs to hatch in an incubator.

“The incubator is probably the most expensive start-up investment required for quail production,” Mckenzie says.

Egg production is also not a constant, but fluctuates over time.

“If you go big, you’ll need to find a market for fresh and pickled eggs, or you’ll sit with a lot of wastage. I used to supply the market with about 1 000 eggs a week,” he says.

Mckenzie says that quail is a wonder food because of its high nutritional value.

“The biggest problem in South Africa, however, is that we do not have a quail-eating culture. Until we develop one, the market will remain limited.”