For the best spray application results, farmers need to use the right product at the right time, follow the instructions and, most importantly, apply the product correctly. Failure to do so will reduce the efficacy of the product, increase the risk of developing resistance to the active ingredient, and drive up production costs.

“Remember, it’s money out of your pocket if the application doesn’t hit the target,” Jack Pickering, technical field scientist at Syngenta, told delegates at a Knowledge Hub event presented by Syngenta and John Deere in Napier in the Western Cape at the end of September.

According to Pickering, there are five factors that influence spray quality and deposition; these are the weather, droplet size, nozzle pressure, application speed, and boom height. Since farmers have little control over the weather, it is more profitable to focus on the other four factors.

Size matters

In terms of droplet size, Pickering said, farmers should generally avoid droplets smaller than 150 microns, classified as extremely and very fine, as these are highly susceptible to drift and evaporation. A droplet of 150 microns, for instance, weighs half as much as a droplet of 190 microns, and a quarter as much as a droplet of 240 microns.

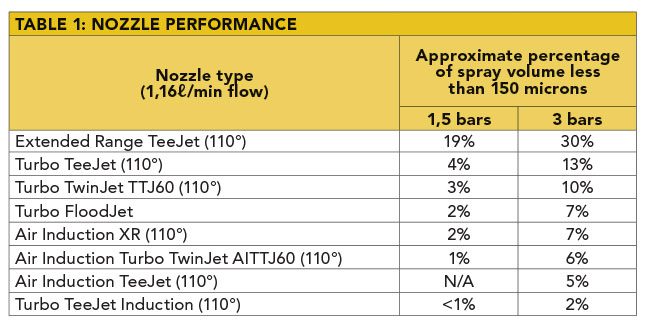

He added that the type of nozzle used has a dramatic effect on the size of the droplets. A VisiSize study performed by Oxford Lasers, for example, found that using the Extended Range TeeJet nozzle resulted in 19% of the spray being 150 microns and smaller when used at 1,5 bars of pressure, and this increased to 30% at three bars.

Using the Turbo TeeJet resulted in 4% of the spray being 150 microns and smaller at 1,5 bars, and this rose to 13% at three bars.

In comparison, the Turbo TeeJet Induction nozzle, which has the same flow rate, resulted in less than 1% of the droplets being 150 microns or smaller at 1,5 bars, and 2% at three bars. (See Table 1 for more information about the performance of other nozzles.)

“The study illustrates that the risk of spray drift and evaporation can be reduced significantly merely by changing the type of nozzle you use. So make sure you know what size droplets your nozzles produce to ensure good coverage,” said Pickering.

But bigger is not necessarily better. Pickering explained that small droplets result in a better coverage than larger droplets. The challenge is therefore to find a happy medium between droplet size and spray coverage.

Under most conditions, he said, medium-sized droplets measuring between 226 and 325 microns are better than coarser droplets measuring from 326 to 400 microns. When increasing to over 650 microns, droplets are classified as extremely coarse.

For ground applications, however, applications should preferably be between very and extremely coarse (between 325 and 650 microns) to hit the target in an optimal manner.

To increase coverage, Pickering suggested increasing the volume of water used with the product. He refers to a study according to which the coverage and retention of coarse droplets, mixed with 112ℓ water/ ha, was found to be better than medium-sized droplets mixed with 38ℓ water/ha.

Medium-sized droplets mixed with 75ℓ/ha or 112ℓ/ ha will give better coverage and retention than fine droplets mixed with 38ℓ/ha.

Pressure and speed

A nozzle’s output is affected by various factors. Firstly, the angle of the nozzle becomes narrower as pressure is decreased, resulting in the spraying solution being applied over a smaller area, and vice versa when the pressure is increased.

Pickering explained that a nozzle might apply the solution at a 90° angle at a pressure of 1 bar, increasing to 110° when applied at a pressure of 2,75 bars, which is more desirable as it will result in better crop coverage.

Secondly, the pressure is usually lower with coarser droplets, and higher with finer droplets.

Nozzles are also designed to operate at specific pressure ranges, which should be considered before deciding on a flow rate.

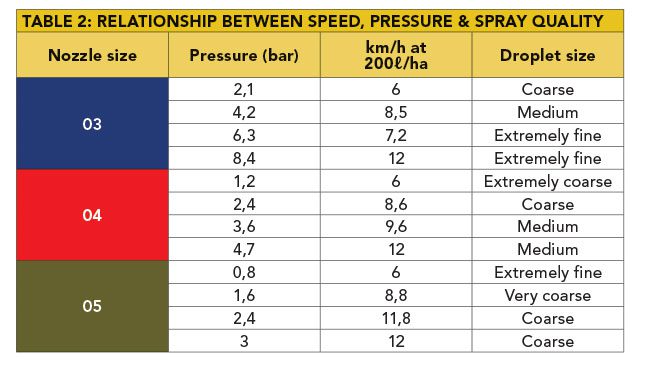

When it comes to delivery speed and pressure, Pickering pointed out that to double the flow of a nozzle, the pressure would have to be increased fourfold. Again, the higher pressure might not be achievable with some nozzles. (See Table 2 for the different speeds required to achieve 200ℓ/ha).

Easy does it

While farmers are obviously keen to cover as much of their land as possible during spraying windows, Pickering warned that speed does not always translate into better performance.

“From studies done in the UK, we’ve seen that spray should not be applied at speeds of more than 12km/h. Going faster results in turbulence behind the boom, which in turn affects the efficacy of the spray product.”

Pickering added that the closer to the ground the boom is, the better, with 50cm to 90cm being the height to aim for, and 50cm the ideal. A few sprayers, however, can be operated at a lower boom height.

He pointed out that increasing the boom height from 50cm to 1m will increase the chances of drift more than tenfold, resulting in a smaller chance that the application will give sufficient protection. This may be exacerbated by the choice of nozzle, even if an air induction nozzle is used.

Sprayer technologies that make a difference

New sprayer technologies, such as John Deere’s ExactApply, enable farmers to save water and chemicals by increasing sprayer-application efficiency.

Sunnyboy Moyana, tactical marketing planner of precision agriculture and intelligent solutions at John Deere Africa Middle East, says that the technology allows farmers to maintain a consistent droplet size in a wider application of speed range, and achieve greater accuracy of spray rate with turn compensation.

He adds that John Deere’s advanced A and B nozzle designs enable farmers to reduce overlapping, over-application, crop burn and off-target drift by offering individual nozzle control and automatically switching some of the nozzles on and off as needed.

When going around turns, the ExactApply system varies the rate at which nutrients are applied. When the equipment turns, the nozzles at the end of the boom automatically spray faster than those closer to the sprayer to make up for the speed differences between two ends.

Moyana says studies have shown that the technology improves spray accuracy by 22% by reducing spray drift, and results in 2% to 5% savings in herbicide and pesticide costs.

Moreover, farmers don’t have to buy new spraying equipment to access the technology; they can simply purchase a performance upgrade ExactApply (year- and model-specific) and fit it onto their existing John Deere sprayer. They should nevertheless speak to a consultant at a local certified John Deere dealer to ensure the compatibility of their machines, Moyana advises.

John Deere has also released its BoomTrac Pro 2, which helps to increase application efficiencies by better managing boom height and using pressure recirculation to prime the boom. This results in the uniform distribution of product across the boom, less nozzle clogging and a uniform spray pattern.

It also helps to reduce boom damage and operator fatigue, as operators no longer have to stop and physically check on a boom to maintain proper height above the crop.

Hein Snyman, tactical marketing planner at John Deere, explains that John Deere’s new 612R crop sprayer is already fitted with ExactApply and enables pressure recirculation and pressure reclaim. The sprayer has a 265kW engine and a boom length of 27,4m to 40m. It comes with CommandDrive, which enables fuel savings of more than 20% compared with equivalent-sized sprayers, improved traction during challenging conditions, and the coverage of a wider area per day.

CommandDrive also significantly reduces cab noise, which, in combination with the large size of the cabin and improved comfort of the cabin, enables drivers to work for longer hours.

Various spray tank sizes are currently available, with the maximum of 6 000ℓ currently being brought into South Africa.

Email Sunnyboy Moyana at MoyanaSunnyboy@JohnDeere.com, or Hein Snyman at SnymanHein@JohnDeere.com.

Email Jack Pickering at jack.pickering@syngenta.com.